This manual provides essential guidance for operating the X Pack 7 Drone‚ ensuring safe and effective use. It covers features‚ safety tips‚ and maintenance instructions for optimal performance.

1.1 Importance of the Manual for Drone Operation

The manual is crucial for understanding the X Pack 7 Drone’s features‚ ensuring safe operation‚ and troubleshooting issues. It provides detailed safety guidelines‚ maintenance tips‚ and legal compliance information‚ helping users optimize performance and enjoy a seamless flying experience.

1.2 Overview of the X Pack 7 Drone Features

The X Pack 7 Drone boasts a foldable design‚ 1080P HD FPV camera‚ and altitude hold for stable flight. It supports real-time video transmission‚ app functionality‚ and is portable for easy transport. Designed for users aged 14+‚ it offers ease of control‚ making it ideal for both beginners and experienced pilots.

Where to Download the X Pack 7 Drone Manual PDF for Free

The X Pack 7 Drone manual is available for free download from trusted sources like Attop and ORKNELY‚ ensuring easy access to essential operating instructions.

2.1 Reliable Sources for the Manual

Trusted platforms like Attop and ORKNELY offer the X Pack 7 Drone manual for free. These sources provide high-quality‚ authentic PDFs‚ ensuring users access accurate and comprehensive guides.

2.2 Step-by-Step Guide to Downloading the PDF

Visit trusted websites like Attop or ORKNELY. Search for “X Pack 7 Drone Manual.” Select the PDF file‚ click “Download‚” and wait for the process to complete. Ensure your device has enough storage. Once downloaded‚ open the file to access the guide. For any issues‚ refer to the website’s support options.

Key Features of the X Pack 7 Drone

The X Pack 7 Drone features a foldable design‚ HD FPV camera‚ real-time video transmission‚ altitude hold‚ and easy control. It is portable and supports app functionality for enhanced user experience.

3.1 Foldable Design and Portability

The X Pack 7 Drone’s foldable design enhances portability‚ making it easy to carry and store. Its compact structure allows for seamless transportation without compromising performance‚ perfect for on-the-go use and storage convenience.

3.2 HD FPV Camera and Real-Time Video Transmission

The X Pack 7 Drone features an HD FPV camera‚ delivering stunning 1080P real-time video transmission. This capability provides users with an immersive flying experience‚ capturing high-quality aerial footage and photos with exceptional clarity and detail.

3.4 Altitude Hold and Easy Control

The X Pack 7 Drone features an altitude hold function‚ enabling stable and steady flight. This mode simplifies operation‚ allowing users to focus on navigation without constant throttle adjustments‚ making it ideal for beginners and smooth indoor or outdoor flights.

Safety Guidelines for Operating the X Pack 7 Drone

Ensure safe operation by following pre-flight checks‚ avoiding obstacles‚ and maintaining a safe distance. Always keep the drone away when in motion and turn it off after flights.

4.1 Pre-Flight Safety Checks

Before each flight‚ ensure the drone and remote are fully charged. Inspect propellers for damage‚ check battery installation‚ and confirm all lights and controls are functioning properly. Calibrate the drone if necessary and ensure the environment is clear of obstacles. Always power on the drone before the controller for proper pairing.

4.2 Operating in Indoor and Outdoor Environments

For indoor flights‚ choose open spaces with minimal obstacles. Ensure the drone is set to indoor mode for stability. Outdoor flights require calm weather conditions‚ avoiding strong winds or rain. Always maintain line of sight and keep the drone away from restricted airspace or sensitive areas for safe operation.

4.3 Age Recommendations and User Responsibilities

The X Pack 7 Drone is recommended for users aged 14 and above. Operators must adhere to local aviation regulations‚ ensure safe distances from obstacles‚ and avoid flying near sensitive areas. Users are responsible for maintaining the drone’s condition and following all safety guidelines to ensure safe and enjoyable operation at all times.

Preparing for the First Flight

Before the first flight‚ ensure the drone and controller are fully charged and paired. Check for a safe‚ open area‚ and follow the manual’s setup instructions carefully.

5.1 Unboxing and Initial Setup

Begin by carefully unboxing the X Pack 7 Drone and its accessories. Inspect all components for damage. Follow the manual’s step-by-step guide to assemble and configure the drone for its maiden flight‚ ensuring everything is securely attached and properly aligned for safe operation.

5.2 Charging the Battery and Remote Controller

Charging the X Pack 7 Drone and remote controller is essential for optimal performance. Use the provided USB charger for the drone battery‚ ensuring it’s fully charged before first use. The remote controller requires 4x AA batteries. The drone offers a flight time of 9-10 minutes‚ with a charging time of approximately 120 minutes. Always follow safety guidelines to avoid overcharging.

5.3 Pairing the Drone and Controller

To pair the X Pack 7 Drone and controller‚ power on the drone first‚ then turn on the remote controller. The LED indicators will flash‚ confirming the pairing process. Ensure the connection is stable before flight. If issues arise‚ recalibrate the drone and repeat the pairing steps for optimal performance and control stability.

Battery Information and Flight Time

This section provides details on battery specifications‚ installation‚ and maintenance. The X Pack 7 Drone offers a flight time of 9-10 minutes with a 120-minute charging time. A low battery warning ensures safe landings.

6.1 Battery Installation and Maintenance

Properly install the battery by aligning the terminals and securing it firmly. Regularly check for wear and tear‚ ensuring clean connections. Replace damaged batteries immediately to prevent performance issues. Store batteries in a cool‚ dry place when not in use to maintain their longevity and efficiency. Always follow safety guidelines provided in the manual.

6.2 Flight Duration and Charging Requirements

The X Pack 7 Drone offers a flight duration of approximately 9-10 minutes. Charging the battery requires about 120 minutes. Ensure the battery is fully charged before each use for optimal performance. Avoid interrupting the charging process to maintain battery health and longevity. Always refer to the manual for specific charging instructions and safety precautions.

6.3 Low Battery Warning and Safety Measures

The drone signals a low battery with indicator lights. Land immediately when warned. Avoid flying over water or obstacles. Turn off the drone and controller post-flight. Store batteries properly to prevent damage. Regular charging and maintenance ensure prolonged battery life and safe operation‚ as outlined in the manual for optimal user experience and safety protocols.

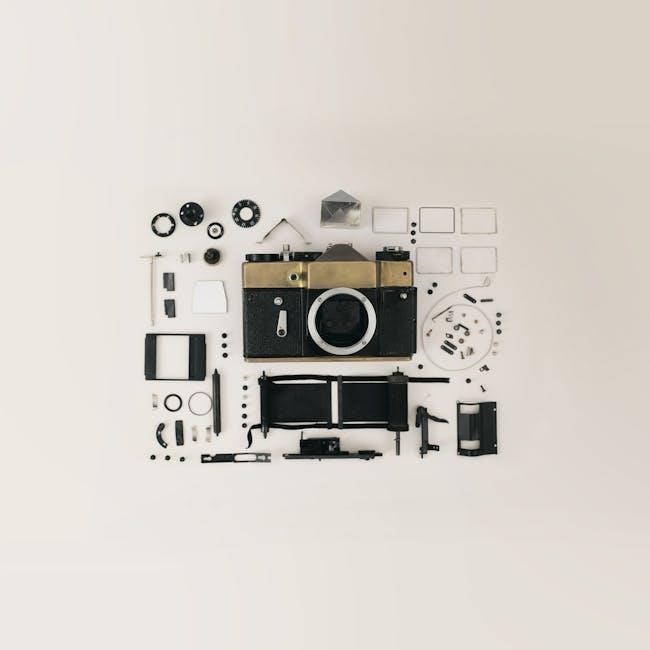

Understanding the Drone’s Components

Familiarize yourself with the drone’s parts‚ including motors‚ propellers‚ and the HD camera. The manual provides a detailed diagram to identify each component for easy maintenance and troubleshooting‚ ensuring smooth operation and enhancing your flying experience with the X Pack 7 Drone.

7.1 Drone Diagram and Parts Identification

The manual includes a detailed drone diagram‚ labeling key components like motors‚ propellers‚ and the HD camera. This visual guide helps users identify each part‚ ensuring proper assembly and maintenance. Understanding the layout enhances troubleshooting and overall operation‚ making it easier to handle repairs and optimize performance for the X Pack 7 Drone.

7.2 Mobile Phone Holder and Mounting Options

The X Pack 7 Drone features a built-in mobile phone holder‚ allowing users to secure their device for FPV viewing. Adjustable mounts accommodate various phone sizes‚ ensuring a stable connection. This feature enhances real-time video transmission‚ providing an immersive flight experience with HD vision directly through the drone’s camera system.

7.3 Folding and Unfolding the Drone Arms

Folding the X Pack 7 Drone arms enhances portability‚ making it easy to carry. To unfold‚ gently pull each arm outward until they click into place. Ensure arms are securely locked for stable flight. Regularly check hinges for smooth movement and clean them to maintain functionality‚ as outlined in the manual for optimal performance.

Camera and FPV Capabilities

The X Pack 7 Drone features a 1080P HD FPV camera‚ offering real-time video transmission. Capture stunning aerial photos and enjoy seamless First-Person View for immersive flying experiences.

8.1 HD Vision and FPV Real-Time Transmission

The X Pack 7 Drone’s HD FPV camera delivers 1080P resolution‚ providing crystal-clear real-time video transmission. This feature allows pilots to experience immersive First-Person View‚ enhancing control and enjoyment during flights. The FPV system ensures smooth and stable transmission‚ making it ideal for both recreational and professional aerial photography and videography purposes.

8.2 Using the Camera for Aerial Photography

The X Pack 7 Drone’s HD camera is designed for capturing stunning aerial photos. With 1080P resolution‚ it ensures sharp images and vibrant colors. The foldable design allows for easy transport‚ making it perfect for outdoor photography sessions. Use the FPV feature to frame shots in real-time‚ enhancing your creative control and precision while shooting from the skies.

8.3 App Support for Enhanced Functionality

Enhance your X Pack 7 Drone experience with dedicated app support. The app offers real-time FPV transmission‚ gesture controls‚ and customizable settings for optimal performance. It also enables firmware updates‚ ensuring your drone stays up-to-date with the latest features and improvements for a seamless flying experience.

Calibration and Pairing Procedures

Calibration ensures accurate flight performance. Pairing the drone and controller is essential for smooth operation. Resetting the device can resolve connectivity issues. Follow the manual for detailed steps.

9.1 Calibrating the Drone for Accurate Flight

Calibration is crucial for precise drone operation. Ensure the drone is on a flat surface and follow the manual’s step-by-step guide to align sensors and ensure stable flight performance. Proper calibration prevents drift and enhances control accuracy‚ making your flying experience smooth and enjoyable. Always recalibrate after firmware updates or prolonged storage.

9.2 Re-Pairing the Drone and Controller

Re-pairing ensures seamless communication between the drone and controller. Turn on the drone first‚ then the controller‚ and follow the manual’s pairing sequence. This process synchronizes the devices‚ restoring optimal control and functionality. Regular pairing checks are recommended to maintain reliable operation during flights. Always refer to the manual for detailed steps and troubleshooting tips.

9.3 Resetting the Drone When Necessary

Resetting the drone restores default settings‚ resolving connectivity or firmware issues. Power off the drone and controller‚ then press and hold the reset button. Release after five seconds and restart. This process ensures proper functionality and compatibility‚ especially after updates or pairing issues. Always reset before recalibrating for optimal performance and stability.

Maintenance and Care Tips

Regular cleaning prevents dust buildup‚ proper storage avoids damage‚ and firmware updates ensure optimal performance. Follow these tips to maintain your drone’s longevity and functionality effectively.

10.1 Regular Maintenance for Optimal Performance

Perform routine checks on propellers‚ motors‚ and battery connections. Clean the drone’s body and camera lens to ensure clear vision. Regularly update firmware and software to enhance functionality and fix issues. Proper maintenance ensures smooth operation and extends the drone’s lifespan‚ keeping it in top condition for every flight.

10.2 Cleaning and Storing the Drone Properly

Use a soft cloth to gently remove dirt and debris from the drone’s surface. Avoid harsh chemicals to prevent damage. Store the drone in a dry‚ cool place‚ away from direct sunlight. Use the original packaging or a protective case to safeguard against scratches and dust. Proper storage ensures long-term functionality and appearance.

10.3 Updating Firmware and Software

Regularly update the drone’s firmware and software to access new features‚ improve performance‚ and fix bugs. Use the official app or website to download updates. Follow the manual’s step-by-step instructions to ensure a smooth update process. Always use a stable internet connection and fully charge the drone before updating to prevent interruptions.

Troubleshooting Common Issues

This section addresses common problems like connectivity issues‚ battery malfunctions‚ and flight instability. Follow the manual’s solutions to resolve these problems efficiently and ensure smooth drone operation.

11.1 Diagnosing Battery and Charging Problems

Identify common battery issues like short flight times or charging malfunctions. Check for damaged connectors or debris. Ensure proper battery installation and verify charger functionality. Flight time is approximately 9-10 minutes‚ with a 120-minute charging period. Low battery warnings trigger during flight‚ and pairing issues may occur if the drone isn’t powered on first.

11.2 Resolving Connectivity Issues

Ensure the drone and controller are properly paired. Restart both devices and recalibrate if necessary. Verify the remote controller’s battery level and check for physical obstructions. If issues persist‚ reset the drone and repeat the pairing process. Ensure the drone is powered on before the controller for proper connection and functionality.

11.3 Addressing Flight Stability and Control Problems

Check for proper calibration and ensure the drone is on a flat surface. Restart the drone and controller‚ then recalibrate. Verify no obstructions are affecting the sensors. If instability persists‚ reset the drone to factory settings and repeat the pairing process. Ensure all firmware is up to date for optimal performance and control.